Precision engineering is a field dedicated to creating high-accuracy components and systems. It plays a critical role in various industries, including aerospace, automotive, and electronics. The demand for meticulous accuracy and reliability in these sectors makes precision engineering indispensable. As technology advances, the tools and techniques used in this field continuously evolve to meet increasing precision demands.

Let’s explore the various tools and techniques used in precision engineering to achieve optimal performance. We will delve into the significance of custom power supplies in enhancing the accuracy and reliability of precision engineering tools. Additionally, we will examine how these advanced techniques contribute to innovation and efficiency across different industries.

Tools Used in Precision Engineering

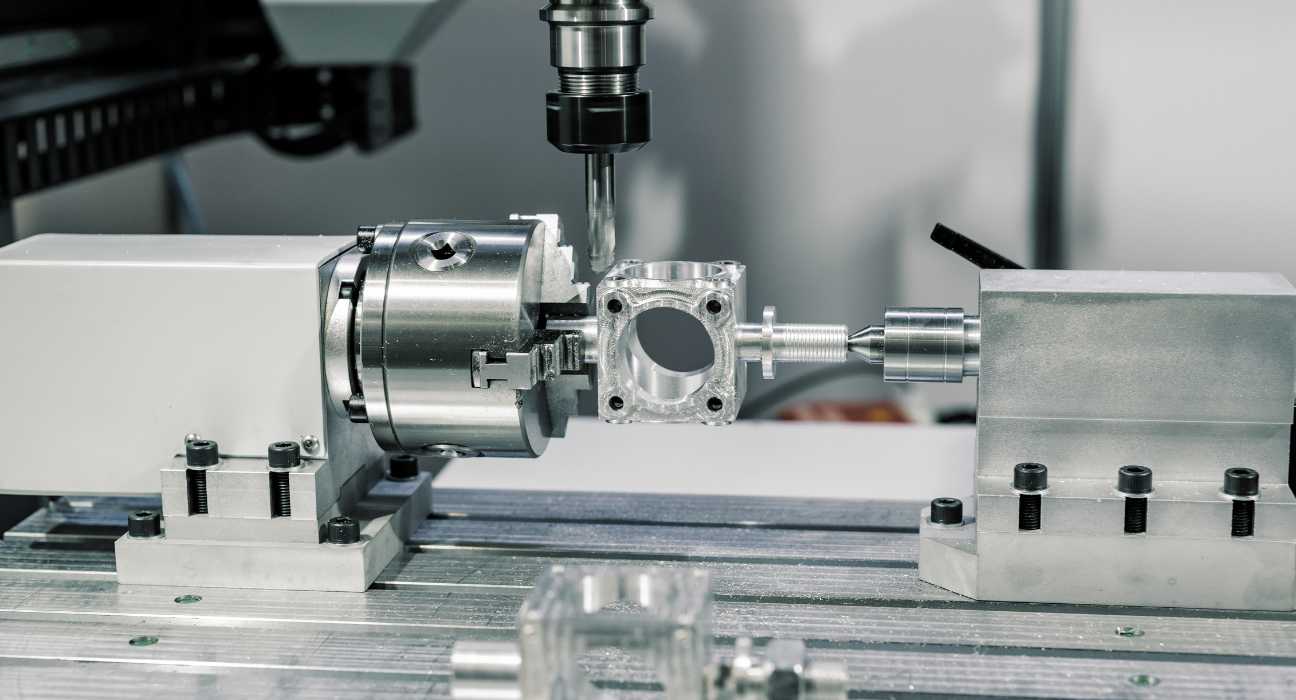

Precision engineering relies on a variety of sophisticated tools to achieve the highest levels of accuracy. These tools are essential for tasks ranging from micro-machining to large-scale manufacturing. Some of the most commonly used tools include:

- CNC Machines: Computer Numerical Control (CNC) machines are fundamental in precision engineering. They use pre-programmed software to control the movement of machinery and tools, enabling the production of highly accurate components. CNC machines can perform various operations such as drilling, milling, and turning with exceptional precision.

- Coordinate Measuring Machines (CMM): CMMs are used to measure the physical geometrical characteristics of an object. They provide precise measurements by touching the object with a probe and are crucial for quality control in manufacturing processes.

- Laser Cutting Tools: Laser cutting tools offer unparalleled precision and are widely used in precision engineering. They use focused laser beams to cut materials with high accuracy, which is essential for producing intricate designs and components.

- Optical Microscopes: Optical microscopes are used for inspecting and measuring very small parts. They provide a high level of detail, which is necessary for ensuring that components meet stringent specifications.

Techniques for Optimal Performance

Several advanced techniques are employed to achieve optimal performance in precision engineering. These techniques ensure that every component produced meets the highest standards of accuracy and reliability.

- Computer-Aided Design (CAD): CAD software allows engineers to create detailed 3D models of components. This digital representation helps in visualizing and refining designs before actual production, reducing errors and enhancing precision.

- Finite Element Analysis (FEA): FEA is a simulation technique used to predict how a component will react to real-world forces such as heat, vibration, and other physical effects. This analysis helps in optimizing the design and ensuring the component’s durability and performance.

- Surface Finishing: Surface finishing techniques, such as grinding, polishing, and coating, are crucial for achieving the desired surface quality and dimensional accuracy. These processes enhance the performance and longevity of precision components.

- Quality Control Processes: Rigorous quality control processes, including statistical process control (SPC) and Six Sigma methodologies, are implemented to maintain high standards. These processes involve continuous monitoring and improvement to ensure consistency and precision.

The Role of Custom Power Supplies

Custom power supplies are integral to the accuracy and reliability of precision engineering tools. They provide stable and precise power, which is crucial for the performance of sensitive equipment.

- Enhanced Stability: Custom-made supplies are designed to provide consistent voltage and current, minimizing fluctuations that can affect the performance of precision tools. This stability is essential for maintaining the accuracy of CNC machines, laser cutters, and other equipment.

- Improved Efficiency: By providing the exact power requirements for specific tools, custom-made supplies enhance the efficiency of precision engineering processes. They reduce energy waste and ensure that tools operate at their optimal performance levels.

- Increased Reliability: Precision engineering tools require reliable power sources to function correctly. Made-to-order power supplies are built to withstand the demands of high-precision environments, offering durability and long-term reliability.

- Tailored Solutions: Made-to-order power supplies can be tailored to meet the specific needs of different precision engineering applications. This customization ensures that the power supply matches the unique requirements of each tool, further enhancing its performance.

Innovations in Precision Engineering

The continuous advancements in precision engineering tools and techniques drive innovation across various industries. The integration of made-to-order power supplies into these systems plays a significant role in these innovations.

- Miniaturization: The ability to produce smaller and more intricate components has opened up new possibilities in electronics, medical devices, and other fields. Precision engineering techniques, supported by made-to-order power supplies, enable the production of these tiny yet highly accurate parts.

- Automation: The automation of precision engineering processes through CNC machines and robotic systems has increased productivity and reduced human error. Custom-made power supplies ensure that these automated systems receive the precise power they need to operate efficiently.

- Sustainable Practices: Precision engineering is also contributing to sustainability efforts. Techniques such as additive manufacturing (3D printing) reduce material waste and energy consumption. Custom-made power supplies help in optimizing the energy use of these innovative processes.

- Advanced Materials: The development of new materials with superior properties, such as composites and advanced alloys, is made possible through precision engineering. Custom-made power supplies support the sophisticated equipment needed to work with these materials.

Precision engineering is at the forefront of technological advancement, driving innovation and efficiency in various industries. The tools and techniques used in this field are continuously evolving to meet the demands for higher accuracy and reliability. As we look to the future, the continued integration of advanced techniques and tailored power solutions will undoubtedly lead to even greater achievements in precision engineering.